Southbank Place is a luxurious residential complex located in the heart of London’s South Bank. The apartments range from studios to four-bedroom units, all of which are designed with modern and sleek interiors.

The location of South Bank Place is unbeatable, with easy access to some of London’s most iconic landmarks, including the London Eye, the National Theatre, and the Tate Modern. The area is also home to a variety of restaurants, cafes, and shops, making it a vibrant and bustling neighbourhood. You’ll also get a front row seat to London’s New Years’ fireworks display without leaving your home.

Overall, South is definitely worth considering.

The development was by Braeburn Estates, a joint venture between Canary Wharf Group Plc and Qatari Diar Real Estate Company. They and their design teams at Johnson Naylor & Goddard Littlefair had specific colour palettes that they wanted to showcase in different buildings. The design brief also called for a high-end contemporary look, this meant, that despite the scale of project, most of the timber needed to be a very select Prime grade of Oak.

Herein, lay the challenge, sourcing Prime grade Oak is one thing, sourcing thousands of m2 of it and keeping the tonal value even to allow exceptional colour control over a project that would take years to complete is another.

By utilising our extensive knowledge of manufacturing and sourcing ability, we sourced the material from a single forest, thereby reducing the risk of significantly different colours or patterns that we would have been exposed to had we tried to source from multiple places. This certainly gave us a great starting point. Furthermore, in keeping with our strict sustainable sourcing code of practice, all the Oak was FSC® 100% certified.

During production, we continuously selected and critiqued every board for conformity. We worked with the designers to ensure we were creating the right colours for them.

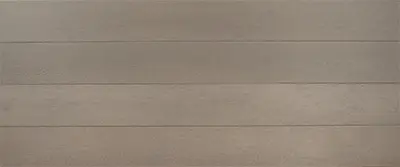

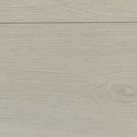

In the main apartments for buildings 4a & 4b (which were superbly fitted by Ruddy Joinery) there were two colour palettes for clients to choose. The dark palette option is a stunning brushed and deep fumed Oak with a gentle lime through the grain (product code E153); it’s a Prime grade Oak with an allowance for colour variation to give a warmth whilst delivering on a luxurious modern aesthetic. The light colour option is a gently fumed Prime grade Oak (product code TW-E615). This floor captures the classic look of an established Oak floor, slightly darker than unfinished (or raw) Oak, but every bit as familiar. Again, you can’t help but feel like you’re in a carefully and thoughtfully designed space. It really is a testament to the interior designers.

In buildings 6 & 7 there were a number of floor options for clients to choose for the main apartments. These ranged from brushed and fumed select grade Oak (product code E124), Smoked brushed Oak (product code TW-E707) an accompanying Smoked rustic Oak herringbone parquet (TW-E907) and an American Black Walnut (product code E509). These were installed by SJE Carpentry.

We also created Versailles parquet panels for one of the penthouses, these were painstakingly handmade and oiled to the clients requested. The panels were 1000x1000mm, featuring FSC certified Oak and a Birch ply backing layer, these panels along with the accompanying border planks are a true eye-catcher in this elite penthouse.

Given the strict design and aesthetic requirements. Both the developer and the design teams were regularly inspecting the fit-outs and critiquing the flooring. Even to the point of walking around with a ruler to measure any knots. The result? The design team were ecstatic with the products we created for them, with no rejections over normal wastage allowances.

Our position, as a manufacturer and client-focused business meant we could not only create and deliver a premium product whilst keeping to budget requirements, but along with our first-class quality processes meant that the flooring installations went smoothly and continued on budget. Saving the contractor, the developer and the client time and money. The Solid Wood Flooring Company specialises on developments like this. We work with Canary Wharf, Ballymore, Berkeley Homes and many others, providing solutions, creating products and delivering exceptional quality time and time again. If you’re working on a project that requires timber, laminate or LVT-type flooring please get in touch, we’re here to help.

At The Solid Wood Flooring Company, we take pride in our long-standing partnership with Horohoe Construction. For several years, we have been collaborating with them, supplying top-quality engineered wood flooring to enhance their projects. Our expertise in manufacturing and delivering a wide range of flooring solutions has enabled us to contribute to numerous developments and fit-outs.

One of the notable projects we’ve worked on with Horohoe Construction involved supplying our exquisite Impervia herringbone flooring. This premium flooring option has been chosen for Horohoe’s meeting area and showroom, where they proudly display their cabinetry. The Impervia herringbone flooring not only adds a touch of elegance but also offers exceptional durability, making it a perfect choice for high-traffic areas.

With our extensive experience and commitment to excellence, we specialise in manufacturing and delivering various types of flooring solutions for larger developments and fit-outs. Whether it’s engineered wood flooring, laminate flooring, or Impervia luxury flooring, we have successfully supplied hundreds of thousands of square metres to cater to diverse project requirements. Our versatile range of products ensures that we can meet the unique demands of each project.

Currently, Horohoe Construction is working on the London Docks project for Berkeley Homes, and we are thrilled to be a part of this prestigious endeavour. Our herringbone basket weave flooring has been selected for installation, adding an extra layer of sophistication to the development. The timeless appeal and intricate pattern of the herringbone basket weave perfectly complement the architectural vision of London Docks, creating a visually stunning and welcoming environment for residents and visitors alike.

Our collaboration with Horohoe Construction has been a testament to our commitment to providing high-quality flooring solutions for diverse projects. As we continue to work together, we look forward to further enhancing the aesthetics and functionality of future projects, cementing our partnership and our shared commitment to exceptional craftsmanship and design.

American Walnut makes a beautiful wood floor with its hue and grain variation. It is quite absorbent, so will soak up oil finishes and will look “dry”, this is normal for walnut.

With our walnut flooring the choice is yours on how you want the finish to look

You can create a glossy finish with Lacquer but this sits on top of the wood rather than penetrating the cell structure and keeps a natural look. It will also scratch, the only way to repair this is to re-sand. With oiled walnut it is easy to maintain and easy to repair.

The image below shows the walnut being fitted by our expert installers who we can introduce to any of our clients.

As you can see the surface is very matt, which is normal. Some people will like this and others will want a more satin shiny look. To increase the shine a little, you would apply some thin maintenance oil with the proper professional equipment, which you can find here and buy online here!

For a higher satin finish look you can use a buffing machine and satin hard wax oil, which will take time to dry but it will give that extra protection and bring out the grain and colour of the walnut. The images below show the floor after this has just been applied during the installation of the chevron.

The American Black Walnut Flooring installed in this country house has underfloor heating in a sand and cement screed. The walnut flooring had been acclimatised whilst the underfloor heating was on and then installed after 7 days. The underfloor heating gradually dried out the hard wax oil factory finish as is to be expected. After 4 weeks, the floor was thoroughly cleaned with the professional wood floor cleaning product Blanchon Natural Soap, this is specially designed to clean any wooden floor as it is PH neutral.

To see our range of American Black Walnut Flooring and order free samples please click here.

In fact you can use this to clean lacquered floors as well as stone floors. We recommend using the lacquered wood floor cleaning kit from Cotswold Home & Garden. The Natural Soap does not leave streaks so you get a perfectly clean floor.

The floor then had a coat of the new heavy duty plus oil applied which has UV inhibitors to help protect the beautiful colour of a walnut floor. In normal circumstances this floor will last a lifetime and will just need cleaning with Natural soap if it gets dirty or with just a soft duster. You can buy a floor cleaning kit from us which has renewable pads for this operation. The pictures show the transformation that just one coat of heavy duty plus oil made to the look for the floor.

BEFORE

We were asked by Canary Wharf to supply and fit out our 220mm wide walnut flooring which is a mixed grade ABCD. However they wanted a more select floor which we were able to do by supplying 20% to 25% more than required to create a stunning near virtual Prime Black American Walnut floor at a fraction of the cost.

A lot of other trades were also completing work at the site including the fit out of show apartments for the Wood Wharf Development. This meant that the floor had to be covered to protect the surface.

The product was our E515 which is a 15mm thick oiled walnut. As you can see even after covering there was still a lot of dust and dirt on the surface after the protection was removed. This is normal at such sites where machining of timber and ceramics has to be undertaken to complete installations of bathrooms, living areas, bedrooms and kitchens.

AFTER

The images below show the difference after the floor has been cleaned and then a coat of oil applied. This process is simple for a professional experienced fitter and not costly.

The natural light really shows the beauty of American Black Walnut Flooring and by using a skilled professional fitter the boards are selected during installation so that they blend in to create the stunning floor you see here.

The product installed here is our 220mm wide, 2200mm long, 15 mm thick ABCD grade engineered walnut where you can see fitted pictures of the product without the selection process used in this Case Study.

Here you can see our B445 Antique Carbonised Bamboo fitted in a designer clothing retail outlet.

This unique bamboo floor was chosen due to its natural strength, luxurious depth of colour which was achieved by carbonising. With a gentle undulation to the surface of the bamboo to provide grip and an aged textural feel. Finished with natural oil for a traditional look.

The pictures below show our beautiful TW-E933 Antique Chevron Parquet floor fitted in a period sitting room of a London Townhouse. The floor was chosen by Laura Stephens of Laura Stephens Design. You can view the Laura Stephens website here.

Laura wanted to create a reception space but very much for ‘adults’, and explained further that, “A friend had used your flooring before which I’d seen and loved. I wanted something with a subtle grey wash but not cold – so many samples were very grey and the warmth of the wood didn’t come through.”

“I love parquet but felt I’d seen a lot of it and the chevron style looked more contemporary yet suited a period room. It’s beautiful as it doesn’t overwhelm the room and is understated. The walls were painted with Designers Guild ‘Cool Marble’ paint which works so well with the tone of the floor.”

Antique Fumed Chevron Parquet Engineered Wood Flooring 60 degree chevron oiled finish

Originally specified for phase two of the Battersea Power Station project we are now fitting this in Parker Tower Convent Garden London. Ramos Catarino are the fit out contractor and because this is a small chevron with a 60 degree angle they are using our professional fitters.

These are apartments and site conditions are always difficult because of the number of different trades working at the same time.

The finish of all our engineered wood flooring is resilient enough to withstand this and all that is needed is a good clean using the latest soap oils. The images below show the different areas and stage of the installation.

The edges of each piece are slightly antiqued and the surface is brushed to add texture.

Setting out is the most the most crucial part of any installation. These site conditions are not perfect and there is still painting to be done and electrical work. In normal circumstances this would not be advisable but when large projects require a fit-out schedule to be met we are left with little choice. Please do not do it this way if it is your home.

The following images show our Antique Oak fitted in the Spitbank Fort Hotel. Matching timber was used around the bar area to create a stunning front, adding to the Antique ambience of the room.

To view more images of Spitbank Fort, or for more information please follow the link below;

http://thebeautifulhousecompany.com/spitbank-fort/

The following images show our Antique Oak fitted in the Spitbank Fort Hotel. Matching timber was used around the bar area to create a stunning front, adding to the Antique ambience of the room.