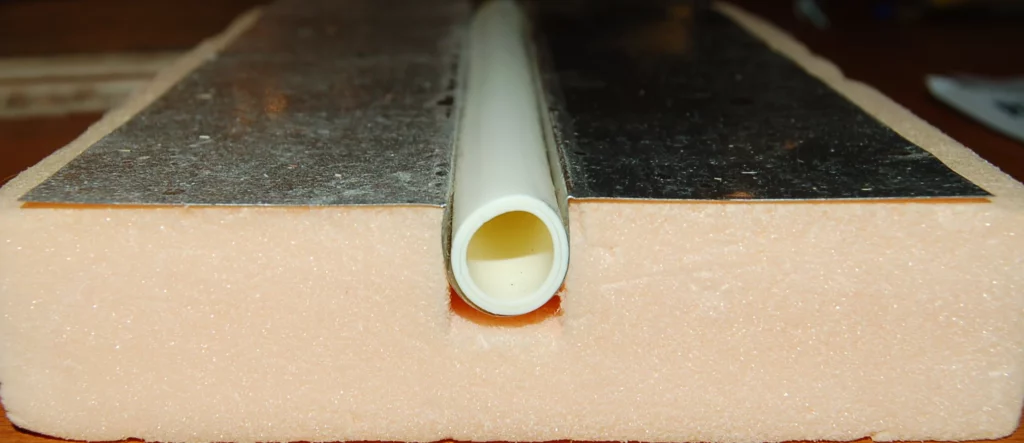

The Solid Wood Flooring Company has developed their engineered wood flooring so it can be glued directly to aluminium spreader plates. These plates are found in certain underfloor heating systems.

Normally these systems have a polystyrene base with an aluminium plate inserted in it before the poly plastic pipe is laid out.

In order to install it correctly, you must ensure that the spreader plates are clean and dry and free of any adhesive or dust.

Following that, you can then use our SW-890 and glue the boards directly to the spreader plates.

Please note: this can only be done with structural engineered hardwood flooring, our structural floor boards are 20mm thick.

In order to ensure correct fitting and adhesion, follow our guidelines in the underfloor heating section. You should also make sure that the surface temperature of the aluminium spreader plate and pipe does not exceed 27 degrees.

By using this tried and tested method, you will need less heat in the pipes as it will unfortunately, transfer directly to the engineered floor.

The two images below show the system with and without a board:

Herringbone Basket Weave Parquet Engineered Wood Flooring

Why buy expensive parquet panels when you can use herringbone basket weave from The Solid Wood Flooring Company for 70% less than you would normally pay for say a Versailles Parquet Panel.

You can see in the image below how our high quality profiling machines can machine the tongue and grooves so that they are very precise with a micro bevel of 0.5mm.

Each piece will have a left or right handed tongue and groove. This engineered wood floor can be laid in two ways as below:

Option 1: Lay in a straight pattern following the walls laterally making sure the walls are perfectly parallel. The image below shows this. In new builds it is normally OK to do this as the rooms should be perfectly square or rectangle. The image below shows the herringbone basket weave in a marketing suite at London Docks. Click on the link below to see the product details.

Option 2: Lay the floor diagonally which means if the walls are not perfectly straight it will not be obvious. The image below shows this in a large house in the London suburbs. Click the image to see the product details.

The TW E931 Brushed Fumed herringbone parquet engineered wood floor laid diagonally used a matching border as the walls were not straight or square.

For the latest pricing and advice on your installation please contact The Solid Wood Flooring Company on 01666 504015

All the Strand Woven supplied by the Solid Wood Flooring Company is made using the hot press method as described below.

Moisture content:

The cold press method is not as easy to control, usually the best moisture content is 10-12% which results warping in dry places and where underfloor heating is used.

The Hot press method controls the moisture content at 8%-10%.

Our Strand Woven Bamboo flooring is customized for the UK market and underfloor heating to keep the boards more stable.

Structural Integrity:

Two edges of cold pressed strand woven bamboo flooring tend to collapse because of the cold press moulding shape. The pressure exerted when it is manufactured (2000 tons without heating) means the two sides are lighter and do not have the same hardness as the middle.

Our hot press method which uses (4000 tons pressure of pressure whilst imparting 140 degrees centigrade temperatures) makes the pressure spread more evenly on the big board. We cut all the four sides of the board for other uses uses like small cutting boards etc. (not flooring where we need integral and structural stability. This means we only use the centre part of the Strand Woven Bamboo for our flooring.

Below is the technical specification of our Strand Woven Bamboo compared to the majority of our competitors. The Formaldehyde and structural integrity is the most concerning when buying cheaper versions of Strand Woven Bamboo Flooring.

Density:

- Cold press:0.97-1.07g/cm3 ,

- Hot press 1.2g/cm3

Hardness:

- Cold press:2500psi,

- Hot press 2700psi.

Size of Flooring:

Cold press strand woven bamboo is normally 96mm wide , any cold pressed strand woven bamboo over this width will have problems over time.

Hot pressed strand woven bamboo can be much wider. The board that is manufactured from the machine is 1860 x1400 x 35mm and can be cut into different sizes for width and thickness for flooring, large planks or panels for different uses in construction e.g. structural beams, butcher counter chopping boards, furniture boards, panels etc.

Colour variation:

Hot pressing bamboo means you get one colour for natural and one colour for carbonised. The colour is controlled by heating like the Anderson’s colour treatment method which is environmental friendly, not like some factories which use stains to make the same colour. Our Bamboo Flooring is done naturally within the manufacturing techniques.

Cold pressing bamboo gives a very large colour variation, at least three different colour shades which will give a lot of variation when the floor is fitted.

Visual Effects:

Cold press strand woven bamboo flooring does not avoid the glue lines when it is pressed and the strands are glued together.

With hot pressed strand woven bamboo these glue lines are never seen as the glues is dry when the strands are pressed together and the heat melts everything into one solid board. This gives a consistent great looking floor with little colour variation.

Green and Environmental Credentials:

- Cold pressed Bamboo: Formaldehyde emission is 0.4mg/l even for the best one.

- Hot pressed Bamboo: Formaldehyde emission is no more than 01-0.2mg/l .

It is because of the glue we apply which is more environmentally friendly than any used in the cold press method which means the formaldehyde in the glue is released very quickly when the boards are made in the hot pressed procedure.

Raw material sourcing and production management:

We have set up a fully environmentally managed bamboo plantation with an efficient production chain. We only manufacture form the best Bamboo which is immediately processed after harvesting which takes place on each plantation every 5 to 6 years and then we replant. Bamboo can grow up to 1 metre a day in its early stages and grows to over 60 feet tall in the space of 5 years. We then use Bona or Natural Oils to finish our flooring to make it the most ecologically friendly in the UK market.

An Oiled Wooden Floor that is sticky

If you have an Oiled Wooden Floor that feels sticky on the top surface and shows up marks and scuffs, you can remedy the situation easily with the correct products.

When excess oil is left on the surface the oxygen in the air cures the surface leaving it sticky and easily marked. This is a common problem that strongly indicates that some excess oil was still present on the surface of the wood flooring after oiling.

How to Fix a Sticky Oiled Wooden Floor:

Note – Before trying this yourself, we recommend you call our experts on 01666 504 015 to check the best procedure in your unique situation.

- Apply a 50/50 mix of Blanchon Natural Soap and water, following the care instructions provided in our ‘Maintaining Oiled Wood Floors‘ guide on our website. In cases of sticky oiled wood boards, clean the boards using a 50/50 ratio of natural soap to hot water as per usual instructions, wait for 5-10mins (so the boards are still wet – never over wet the boards) and proceed to step 2:

- Buff the surface of the floor carefully using a red buffing pad. This will remove the residue from the floor. In extreme situations, you may require a coarse brown buffing pad, but please check in with us on 01666 504015 before proceeding with this.

- Remove any excess solution or ‘gunk’ from the boards using a mop or clean lint-free cloth

- Repeat this process twice over, or for more extreme situations repeat steps 1 through 4 several times. Allow at least one hour for drying if repeating steps 1-4, and once completed allow the floor to dry completely overnight.

Advice – If the situation is not improving, please call our team on 01666 504015 for advice on using stronger cleaners such as Blanchon Powerful Cleaner or Bona Remover.

- In order to add protection to your floor, it is best to apply a new coat of oil. Using the steps noted in our ‘Maintaining Oiled Floors’ guide, re-oil using Blanchon Maintenance Oil.

For more information on caring for your wood floor or discuss any issues you may be having with wood flooring please call our experts on 01666 504 015 or email info@thesolidwoodflooringcompany.com

How to Clean a really grubby dirty Brushed and UV Oiled Oak Floor

Cleaning a brushed UV Oiled Floor:

1 – Thoroughly sweep and vacuum the floor (use the brush attachment/setting on your vacuum cleaner).

2 – Get two large buckets and fill both to two-thirds of the way up with very hot water. Add the Blanchon Natural Soap. Blanchon Natural Soap to one bucket using a mix of 100-200ml of soap to 5 litres of hot water, depending on how dirty your floor is. The other bucket will be for rinsing

3. Make sure you have a clean sponge on squeezy floor mop, then soak it in the hot water bucket containing the natural soap solution, swirl it around to get as much soap into the sponge as possible. Squeeze as much water as possible out of the mop, then clean between 0.5m2 – 1m2 or less per rinse, depending on how dirty the floor is. It is important to not over-wet the floor. The condition of the floor will become noticeable after the first few boards are cleaned, and this will make it easier to know how often to rinse the sponge. Remember to clean down the grain of the boards rather than across them.

4 – Leave floor to dry completely. This usually takes 20 minutes to one hour depending on room conditions.

To Re-Oil a brushed UV Oiled Floor:

If your floor is easily marking it’s likely you need to apply some more oil. This is a simple procedure which is outlined below:

1 – Clean the floor as per the instructions above.

2- Once the floor has dried, apply a single coat of Blanchon Maintenance Oil and buff it in. Get a small container, pour a little oil into it from the Maintenance Oil container, and apply to the floor. If you pour the oil straight from the larger container you will risk having excess oil on the floor, which is a waste and also risks saturating the floor in too much oil for it to absorb.

3- For best results, we recommend use a buffing machine with a white or beige buffing pad. You can work the oil in by hand using a lint-free cloth, though this can take significant effort and can be tricky to complete over a large area before the oil goes tacky. Use a similar lint-free cloth to work the edges of the room that the buffing machine will miss. Tip – If you cannot use a buffing machine you can complete step 2 by working the oil in using a Bona Telescopic Mop with the Applicator Pad accessory; this method will give a more matt finish than buffing.

4- As soon as you have applied a little oil you should spread it and work it into the board. It is not recommended to oil the entire floor and then buff it all in afterwards, as this can leave time for some parts of the floor to go tacky.

5- Once the oil is fully worked in, leave the product to dry for the manufacturer’s recommended time.

If you require any assistance in caring for your brushed and oiled wood flooring, please call our experts on 01665 504 015 or email info@thesolidwoodflooringcompany.com

Blanchon Wood Floor Maintenance Guides

Maintaining a wood floor finished with Blanchon Wood Floor Oil Environment

Light traffic area

Cleaning

Vacuum the floor on a regular basis. From time to time, spray Blanchon LAGOON (ready-to-use neutral cleaner) on the floor and wipe using a micro-fibre mop. Do not use products containing ammonia, abrasive or silicone.

Maintenance

Once or twice a year, depending of the amount of traffic, apply a thin coat of WOOD FLOOR OIL ENVIRONMENT Special Maintenance with a micro-fibre mop or a fine and clean cotton cloth. Allow the floor to dry 30 minutes before reusing the room.

Local renovation

Where the floor is damaged (stain, scratch, cigarette burns, etc.) sand slightly using a fine sand paper to remove the damage then apply 1 or 2 coats of WOOD FLOOR OIL ENVIRONMENT Special Maintenance with a cotton cloth. For a perfect finish, apply a thin coat over the whole floor with a micro-fibre mop. Allow the floor to dry 30 minutes before returning to use.

Major renovation

Give the whole floor a light sanding, carefully vacuum the dust and apply a thin coat of WOOD FLOOR OIL ENVIRONMENT with a short-hair roller. Allow the floor to dry 12 hours before returning to use.

You can download the pdf files here for floors finished with Environment Oil:

Blanchon Environment Oil Maintenance:

2. Heavy traffic area

Cleaning

Vacuum the floor on a regular basis. Once every 2 days, spray Blanchon LAGOON (ready-to-use neutral cleaner) on the floor and wipe with a micro-fibre mop. Do not use products containing ammonia, abrasive or silicone.

Maintenance

Once a month (or once every 2 months, depending of the amount of wear), apply a thin coat of WOOD FLOOR OIL ENVIRONMENT Special Maintenance with a micro-fiber mop or a dry and clean cotton cloth. Allow the wooden floor to dry 30 minutes before returning to use.

Local renovation

Where the floor is damaged (stain, scratch, cigarette burns, etc.) sand slightly using a fine sand paper to remove the damage then apply 1 or 2 coats of WOOD FLOOR OIL ENVIRONMENT Special Maintenance with a cotton cloth. For a perfect finish, apply a thin coat over the whole floor with a micro-fibre mop. Allow the floor to dry 30 minutes before returning to use.

Major renovation

Give the whole floor a light sanding, carefully vacuum the dust and apply a thin coat of WOOD FLOOR OIL ENVIRONMENT with a short hair roller. Allow the floor to dry 12 hours before returning to use.

3. Maintenance of satin lacquered wooden floors under heavy wear

– Wait 10 days after the final application of lacquer, then clean the whole surface with Wood Floor Heavy Duty Cleaner (dilute 10% in warm water). Rinse well with clear water afterwards using a damp mop. Let dry.

– Then apply 2 coats of Varnished Wood Floor Protector 17. Wait 1 hour between coats. Apply thin coats of the product with a mop, a micro-fibre mop or a floor cloth. Always use damp material and not soaking wet ones.

– Vacuum the floor every day. If possible, clean the whole floor with a damp mop.

– Once a week, clean the floor with the Varnished Wood Floor Daily Cleaner using a damp mop. Dilute 1 part of the product in 3 parts of water beforehand.

– The maintenance program will depend on the amount of wear on the floor. On average, apply 1 coat of Varnished Wood Floor Protector 17 once a month after having cleaned the surface.

4. Maintenance of matt lacquered wooden floors under heavy traffic

– Wait 10 days after the final application of lacquer, then clean the whole surface with Wood Floor Heavy Duty Cleaner (dilute 10% in warm water). Rinse well with clear water afterwards using a damp mop. Let dry.

– Then apply 2 coats of Metamat. Wait 1 hour between coats. Apply thin coats of the product with a mop, a micro-fibre mop or a floor cloth. Always use damp material and not soaking wet ones.

– Vacuum the floor every day. If possible, clean the whole floor with a damp mop.

– Once a week, clean the floor with the Varnished Wood Floor Maintenance with a damp mop. Dilute 1 part of the product in 3 parts of water beforehand.

– The maintenance program will depend on the amount of wear on the floor. On average, apply 1 coat of Metamat once a month after having cleaned the surface.

MAINTENANCE AND RENOVATION OF A VERY HEAVY TRAFFIC AREA FINISHED WITH BLANCHON HARD WAXOIL

Regular maintenance

Vacuum on a regular basis. Wipe the floor with a damp mop (never a soaking wet one) every 2 days or so with the NATURAL SOAP for OILED WOOD FLOORS. Before use, dilute 250 mL of the product in 10 litres of water. Avoid ammoniated, abrasive and silicone products.

Specific maintenance

Twice a month (or even once a week in case of very heavy traffic), apply 1 coat of Hard Waxoil Maintenance using the spray method: use a spray and buff right after the application with a buffing machine fitted with a beige pad* or a cotton cloth. Allow the wood floor to dry 1-3 hours before returning to service.

Renovation

Damaged areas (satins, scratches, burns, impacts, etc.) will be sanded slightly using a fine sandpaper followed by an application of Natural Hard Waxoil using a spray. Buff immediately with a buffing machine fitted with a beige pad or a cotton cloth. Allow the wood floor to dry 3-5 hours before returning to service.

in very dirty areas, use the same procedure but with a green pad under the buffing machine instead of a beige one.

How to Maintain Your Lacquered Wood Floor

Choosing a lacquered floor is ideal for a busy environments. At The Solid Wood Flooring Company, all our lacquered boards are finished with high-quality lacquers from Bona.

To keep your lacquered floor looking as good as the day it was laid you’ll need to follow this routine as nessacary:

General/Regular Cleaning

Cleaning a lacquered floor is easy and can be done as many times as you want. The ideal product to use is the Bona Spray Mop. The spray mop is easy to use, and comes with 1ltr of Bona Cleaner. Bona Cleaner gives you a powerful, low-foaming cleaning agent. It washes away dirt better than ever without damaging finishes or leaving any residue. Carefully balanced alkalinity makes it an effective degreaser that won’t harm the wood and can be bought in 4ltr refills.

Simply spray the cleaning agent on to the floor using the trigger mounted on the handle of the mop; then work in the cleaning liquid with the micro-fibre pad on the bottom of the. Continue this action around the area you wish to clean.

Periodic Maintenance

This step is only needed as and when the floor is looking faded or marked. It is good practice to do this once a year or as required depending on traffic (in some heavy use areas like offices, or restaurants every few months may require this step).

- Clean the floor as directed in ‘General/Regular Cleaning’ and allow to the floor to dry fully.

- Apply Bona Freshen Up to floor. Shake the bottle vigorously for a 20secs and then squeeze the bottle to release the liquid inside. Please note, a little goes a long way so don’t over-use the product or you’ll end up with a sticky floor.

- Apply Freshen Up directly to floor in a 3 – 4cm wide wavy line. Work the Freshen Up in to the floor using a Bona Applicator Pad slightly dampened with water. Even out along the grain of the wood.

Allow the floor to dry for a minimum of two hours before use. A second coat may be required. Avoid heavy traffic and replacing rugs or heavy furniture for 24 hours.

Antique oak flooring is normally associated with reclaimed timber for old boards and warehouses that has aged through years of use and abuse. Most of the old barns and factories that had oak flooring have disappeared so the only sustainable option is handmade antique flooring. The products shown here are just an example for see more products and details here.

There are many versions of this in the UK wood flooring market and most use machines to try and replicate the surface and texture of reclaimed Oak. The problem with this method is that the surface indentations become regular and you get a very “false” appearance.

Even where companies profess to “hand scrape” the surface it is still repetitive.

Here at the Solid Wood Flooring Company, we have devised a method whereby our expert craftsmen are specifically trained to prepare the surface of our antique oak floor boards as if they had been on the floor for a hundred years. This means that there are no repetitive patterns showing and you get the most natural reclaimed look possible in a new prepared oak floor.

The following characteristics will be found on our antique oak flooring:

Large and small unfilled knots, although our boards do not contain a large number of knots and they are not dead knots. Dead knots left in a board can fall out or become loose so when comparing products be careful of the very cheap antique floors.

Areas of grain especially the softer grain hand scraped to about a 1mm to 1.5mm depth to give the surface a reclaimed look.

The grain on antique oak flooring will have wide colour variation, heart and some heart shake, occasional cracks and holes. We ensure that the features of the boards have no effect in their strength and all our antique floor boards are structurally sound.

Antique oak flooring is usually wanted for older buildings and we get specifiication for a lot of Grade I and Grade II listed buildings where the old floors have rotted through or due to a major refurbishment where all or some of the floors need to be treated.

It’s easy for property owners and floor fitters to get confused when it comes to whether your wood flooring is covered in your contents or buildings insurance.

At the Solid Wood Flooring company we always recommend gluing your wood floor directly to your subfloor when possible. This means that your floor is a permanent fixture and therefore, covered in your buildings insurance.

We would only suggest floating a floor in extenuating circumstances, such as acoustic issues. Should this be the case, then you would have to ensure this was included in your contents insurance, as it’s not a permanent fixture.

An insurance company could ultimately dispute a claim if you had a floated floor and tried to claim under the buildings insurance. So, always read the small print in your policy and make sure you are covered.

For example: If you had a wood floor in your house that you bought and had fitted £5,000 and it was floated (laid over an underlay); then it may not be insured if you had to make a claim as it would be the same if you tried to claim for a carpet as it’s deemed a non-permanent fixture.

Here at the Solid Wood Flooring Company, we use the Homag Profiling machines to machine tongue and groove on to the edges of our wood flooring boards.

The machines in the picture above, accurately machine tongue and groove down the two long sides and then the two ends of each board, which allows easy installation of our engineered wood floors and helps secure the floorboards together for a great looking and long lasting floor.