Value Engineering Flooring

We value engineer any existing floor specification that is over budget

What is really meant by the term “Value Engineering”?

There are several interpretations of this term, and a couple are listed below.

Value engineering is a systematic analysis of the functions of various components and materials to lower the cost of goods, products and services with a tolerable loss of performance or functionality. Value, as defined, is the ratio of function to cost.

Value engineering is the review of new or existing products during the design phase to reduce costs and increase functionality to increase the value of the product. The value of an item is defined as the most cost-effective way of producing an item without taking away from its purpose.

At The Solid Wood Flooring Company, we have the facilities to value engineer any existing floor specification that is over budget.

Below we’ve noted some of ways we can help you cut costs without compromising quality:

1. Change the grade: Grading of timber is generally listed alphabetically from ‘A’ to ‘F’. At no point does the quality of the timber come into question, only the permissible amount of knotting and character on a board. Starting from ‘A’ grade you’ll see almost no character, this is the highest ‘prime’ grade possible, with minimal knotting and very straight grain. From there more knots, grain patterns and colour variation become gradually more permissible as you work toward ‘F’ grade. For more detailed information please see our grading scale.

2. Change the Structure: Wood flooring can be constructed in a number of ways with various materials. Selecting the right options for your project is crucial to being cost effective. The following are typically available:

a. Solid

b. 3-Layer single species

c. 3-Layer mixed species

d. Plywood backed single species

e. Plywood backed mixed species

We can help you navigate these choices to select the best option for your unique project.

3. Change the thickness of the top layer: We will only use 3mm or 4mm top layers for our engineered boards. Thinner top layers need to be ‘rotary cut’ which is a method where the log is soaked in chemicals to soften the fibres and is then peeled off (similar to how a pencil sharpener works). Whilst this is a cheap production method it is false value as the top layer will always be susceptible to splitting and will not wear very well. Typical thickness of these top layers varies from 0.5mm to 2.5mm. Be mindful that even when value engineering, there are some places you don’t want to save money, the top layer being one of them (much like if you were trying to save money on a car, you wouldn’t want cut back on the effectiveness of the brake system).

4. Properly Finished Flooring: A further temptation is to by unfinished flooring as it is cheaper on the initial purchase than factory finished (pre-finished) options. However, typical finishing coats on site at £15m2, so it becomes instantly more expensive once you’ve factored in contractor costs. The only time unfinished timber should be purchased is if you want to paint the floor, or have a very specific requirement.

Pre-finished is definitely the better option for most projects. Therein you want to make sure that a good quality finish has been applied and that is suits the intended purpose. There is a big difference between quality oils and lacquers to inferior ones. At The Solid Wood Flooring Company, we only use premium oils and lacquers and use the latest coating technology. As we have standardised this in our production process, we’re able to offer this level of quality cost-effectively.

5. Use an alternative to engineered wood flooring: We have developed products that match the colour, texture and feel of our real wood flooring using the latest technology. You can see details of our alternatives further down this page. Impervia is generally 35% less than engineered wood and our Trident laminate is generally 60% less. Both of these wood alternative products are built for commercial use so you can be confident of a long service life with minimal care required.

6. Buy direct from the manufacturer: A large number of wood flooring suppliers are resellers; this means additional margins on the flooring thereby higher costs or bigger quality sacrifices as they don’t truly control production. Whereas, The Solid Wood Flooring Company is the manufacturer with full control of production and no “middle-men” to factor into any costings. This means an immediate saving with true quality and sourcing control.

7. Species selection: There are many wood species available. American Black Walnut as an example is a high value material, easily 20% more than American White Oak. We have developed techniques to colour Oak to better replicate Walnut which provides an enormous saving. European Oak can also be used and we can now use American Red Oak with a special colouring process we’ve developed to create stunning prime grade white Oak floors in high volume at a reduced cost.

A note on material sources – we will only use timber from either FSC or PEFC certified forests which will have stringent harvesting and replanting regimes. We will never allow our supply chain to be tainted with unsustainable timber; that is our commitment to our clients, the planet and ourselves.

Impervia Flooring

With a saving of at least 35% compared to engineered wood, our Impervia range of water-proof, commercial grade flooring is an immediate go-to to reduce supply costs and also installation costs.

We utilise the latest technology and our special efficient processes to create this flooring that looks just like real wood. It has been installed in our main showroom and many people coming in for wood flooring have stood on Impervia and said “this is the wood floor I want” they are shocked to learn it has no timber components.

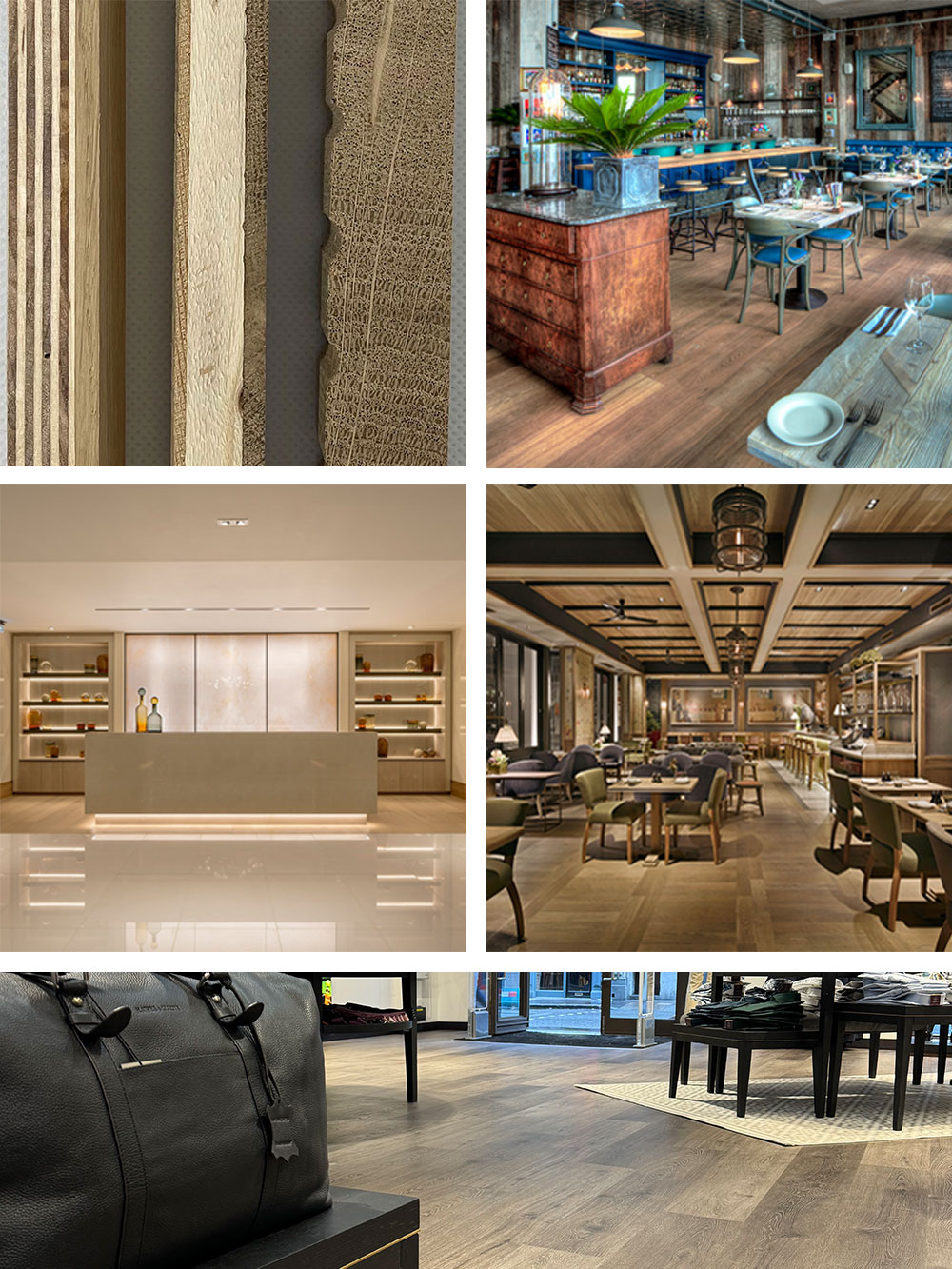

Impervia is designed for heavy commercial use to ensure that it outperforms requirements in any setting. A firm favourite of many housing developers, hotels, restaurants and luxury car showrooms, Impervia is an ideal choice for your project.

Trident laminate Flooring

Trident Laminate offers phenomenal value for money. Despite a 60%+ cost saving compared to engineered wood, this laminate flooring shares many of the features we pride on our wood floors. It is made using FSC certified material. The core features a HDF (High Density Fibre) construction. This makes it stronger and more resilient than most other laminate products on the market (inferior products use an ‘MDF’ core).

This means Trident Laminate will have a longer service-life and superior resistance to damage and spillage than other laminates.

Using massive ultra-HD images of our floors to create the decorative layer, the pattern repeat is exceptionally low making it very difficult to tell this product from a real wood floor. We also use an EIR method to create a wood grain surface texture to again give that real-wood look and feel.

Trident laminate is water resistant as standard, but we can make it with a water-proof finish should it be required. Additionally, we can create the product with the underlay built-in should you wish to see a further saving. Adding underlay typically costs £1m2, which is cheaper than supplying underlay loose, it also saves space (and therefore costs) on deliveries to site and time for the contractor to install.

Trident Laminate is available in plank or herringbone format as well as chevron boards. You can see the Trident Laminate range here.

FOR MORE INFORMATION OR IF YOU ARE STRUGGLING WITH BUDGETS PLEASE GIVE US A CALL ON 01666 504015 OR EMAIL info@thesolidwoodflooringcompany.com

Sustainable Timber Flooring

We are very conscious of our environment and will only supply fully sustainable wood flooring. We are FSC® certified and PEFC™ certified. This section reviews our ethical code of conduct and provides links to our certifications. If you have any more questions on our Responsible Purchasing Policy please call us on 01666 504 015.

Get in touch

Questions or comments? If you can’t find the answer to your question on our site or want to leave some feedback, please fill in the form below.

Join our mailing list

Receive the latest news, offers and inspiration straight to your inbox.