Spitbank Fort was originally built in 1878 and was part of a group of forts designed to defend the mouth of the Solent. As of April 2012, Spitbank Fort, has been owned by Clarenco LLP, and has been renovated for use as a luxury spa hotel and retreat with nine bedroom suites.

This project created challenging circumstances for wood flooring because the structure is metal and is over 130 years old. Surrounded by sea creating high, fluctuating humidity and the structure was round so most of the boards had to be re-manufactured to fit. There were height restrictions because there were numerous arches creating low points and all the services had to be laid on the existing substrate thus raising the finished floor level to accommodate them.

Despite those challenging circumstances PLC Architects created a stunning design and by using the antique flooring captures a wonderful feel of history and elegance.

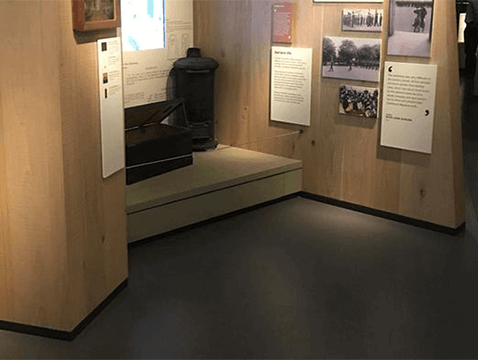

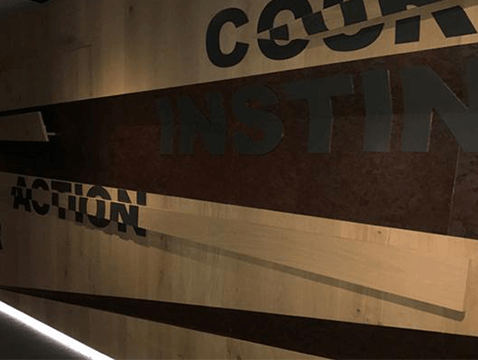

The designers who did the Army museum refurbishment used our band saw CH E780 wide board 240mm to clad the walls. The images below show where they were installed.

You can clad ceilings and walls with our engineered wood flooring as long as a special coat of fire-retardant finish is applied. The CH E780 is finished with a commercial UV cured special oil that is more like a lacquer but very mat.

Please see below for the product used on this project and call us on 01666 504015 for any other information

We were asked by the fit out contractor to supply high quality herringbone parquet engineered flooring in a clean select grade for the very expensive apartments.

They chose two of our special parquet flooring, one with our industrial UV cured white oil finish on white Oak and the other herringbone was our North American Black Walnut with a hard wax oil finish which brings out the beautiful lustre off the natural grain and tones of walnut.

You can see the white oiled herringbone below and the product code is TW E942, the light brushing takes out the softer grain and makes the floor harder wearing and less susceptible to high heels etc.

The Black American herringbone engineered parquet wood flooring is one of the hardest Walnuts available (Apart from the Brazilian Walnut that is illegal) and by using hard wax oil it not only seals the grain but makes the floor easy to clean and repair. There will never be a need to sand the surface and any dents or damage can be easily remedied by using our professional products.

You can see the walnut in the images below and the product code is TW E951.

Please see below for the product used on this project and call us on 01666 504015 for any other information

For the beautiful penthouse atop one of the buildings in South Bank Place, located next to the London Eye, the designers wanted a feature floor with a bespoke colour finish. We worked with the designers at Goddard Littlefair and decided on the timeless design of the Versailles parquet pattern. The designers wanted a show-stopping colour for this floor. We created the Belvedere colour finish; using a mixture of fumed, European Oak and pigmented hard wax oils to create a dark colour tone with red and golden highlights.

To ensure a uniform and quick installation on site; we creating metre square panels with the Solid Oak Versailles pattern positioned by hand onto Birch plywood backing. Having discussed the fit-out process in detail with the fit-out team from SJ Eastern Joinery, we grooved all four sides of the panel and supplied the tongues loose. This gave the fitters flexibility to lay the boards as they saw fit on site. Once we had assembled the panels, the bespoke colour finish was applied; after completing multiple coats the panels were stored to fully cure and harden.

Once the team from SJ Eastern had fitted the flooring on site, they protected it with a soft breathable cover and topped that with hardboard and taped the edges. This allowed the other trades to snag without damaging the floor. Once snagging was complete, the floor protection was removed. As anyone who has been on a building site knows, dust and debris are everywhere and sure enough the flooring needed a final clean and buff with oil to increase the lustre and make it perfect for the wow factor needed in such a stunning project.

The expert team lead by Bardhyl Miskiqi of BRB Flooring came in and cleaned the floor thoroughly, removing plaster dust and other debris by vacuum and cleaning the floor down using a solution of Blanchon Natural Soap and hot water. Once the floor was suitably clean, they applied Blanchon Hard Wax Oil Satin on to the floor and buffed a coat into the floor using a buffing machine equipped with a white buffing pad. This fed the Oak another coat of oil which bolsters the protection against every day use and increased the lustre of the wood highlighting all the colours from that bespoke colour that had been applied at the factory.

Once the oil was properly buffed in, the penthouse door was closed and the floor left to dry and cure. Once curing had completed the furniture was placed in the room and made ready for viewing by the client and new owner and a lifetime of happy memories.

Please call 01666 504015 for more information or click the product image details below.

We were approached by Lindi Reynolds Interiors who was looking for a statement wood floor for their clients home in Surrey. The brief was for a wow-factor floor with a warm, dark hue to the Oak and a unique pattern to the floor.

As we worked with the designer to identify the ideal colour tone, the TW-E931 Fumed Oak herringbone hit all the right notes for the colour, but the client wanted something more than a herringbone pattern. Drawing on experience with another project for a large development in London we suggested a basketweave parquet pattern. Our basketweave is made using our 120mm wide herringbone flooring (such as TW-E931) and a square centre piece that measures 240x240mm. By laying these components in the basketweave pattern you create a stunning statement floor.

In this particular project, the client chose to lay the boards in a diagonal; creating a unique look. The engineered boards are fully bonded to the subfloor using our SW-890 adhesive. As the board construction is engineered, it’s suitable for use with underfloor heating. The expert team of BRB Flooring were able to quickly complete the fit-out according to the clients wishes and hide the perimeter expansion gap under the skirting for a sleek, professional finish.

Whether for a private home, commercial space or residential development; the commercial grade UV Oiled finish is hardwearing and easy to maintain making it ideal for any setting. If you’d like to discuss basketweave parquet for your project please get in touch on 01666 504 015 or info@thesolidwoodflooringcompany.com.

In this particular project, the client chose to lay the boards in a diagonal; creating a unique look. The engineered boards are fully bonded to the subfloor using our SW-890 adhesive. As the board construction is engineered, it’s suitable for use with underfloor heating. The expert team of BRB Flooring were able to quickly complete the fit-out according to the clients wishes and hide the perimeter expansion gap under the skirting for a sleek, professional finish.

Whether for a private home, commercial space or residential development; the commercial grade UV Oiled finish is hardwearing and easy to maintain making it ideal for any setting. If you’d like to discuss basketweave parquet for your project please get in touch on 01666 504 015 or info@thesolidwoodflooringcompany.com.

This is board has been brushed to create an additional texture to the surface of the board, adding grip, especially for animals. The images of the floor give a perfect example of the beautiful flooring in a London home.

The oak has been fumed to give a deep colour tone throughout the top layer, accentuating the natural beauty of the timber. Finished with a hard wearing UV oil this board is suitable for home or commercial environments. It is also FSC® Certified Flooring.

Our TW-E601 Lacquered Oak flooring was used in a spacious home to compliment the the light and airy feel of the open living spaces.

The TW-E601 has been brushed for a textured surface. The oak has been fire fumed for a smokey deeper hue, then a white oil applied to highlight the grain. ABCD graded timber gives mixed range of knots and clean boards for a modern classic looking floor. Finished with a easy maintenance lacquer this floor is suitable for a variety of situations.

The Solid Wood Flooring company have worked with Wildwood Retail for many years and their professional approach to design and project management is inspiring. They chose our select grade UV oiled white board to give an uplift to the Crew Clothing shops and it has been a great success. Please visit www.wildwood.co.uk for more information on other projects completed by Wildwood.

Below is a gallery of images from the Shrewsbury branch that was recently fitted with the brushed oak floor:

All our flooring is finished to be able to be used in both residential and commercial applications. Because of our professional and supportive approach many large International and UK brands are now using our flooring. Hotels, Restaurants, Retail outlets, Banks, Museums and Large offices as well as major tower block developments are now seeing the benefits of using our wood floor solutions that give value for money.

The TW-E108 is a white oiled, brushed oak board. This 15mm thick board sports a 4mm thick top layer and a tough oiled finish, making it suitable for a variety of situations, including use with under floor heating. ABC graded oak allows a small amount of knots and colour variation to highlight the natural accents of oak without compromising the ultra modern styling.

Our E352LN Brushed & UV Oiled Natural Oak flooring was used in this kitchen and living room. The oak is ABC/Select grade for fewer knots and mild, natural colour variation.

The principle idea behind this choice is that the oak gives a warm feel and is adaptable to the changes in decor over the coming decades.

This is the first Bubba Gump Restaurant in Europe and is expected to be a huge success based on the popularity of the USA brand.

After several meetings with the main contractor PEC Contracting we sent two samples of flooring for approval by the American Franchise owners of the Bubba Gump Shrimp Co. restaurants. Once they signed off the accepted sample we then made sure we had stock available for immediate delivery.

They wanted the authentic look that they have in the United States so our Antique Unfinished engineered wood floor was chosen (E109UF) which is 260mm Wide. The boards were fitted using the fully bonded method with SW890 MS Polymer adhesive made for us by Sika Ltd.

Once fitted, the floor then had a builder’s clean and a coat of Satin Gold Maintenance oil which transformed the look and feel of the floor.