Purchasing Wood Flooring – What to Look for

What makes an oak flooring supplier “reliable”?

A reliable European oak flooring supplier is defined not just by the appearance of their boards, but by the consistency, transparency, and long-term performance of their products, particularly when it comes to solid wood flooring.

Reliability means clearly sourced European oak, honest grading, proven manufacturing standards, and realistic guidance on where solid wood floors are suitable (and where engineered alternatives may perform better).

The most dependable suppliers provide full technical specifications, environmental assurances, and expert advice to ensure solid oak flooring looks beautiful, performs as expected, and lasts for decades rather than years.

How to choose a reliable oak flooring supplier in Europe

A reliable European oak flooring supplier should provide verifiable timber sourcing (FSC/PEFC or equivalent), clear product specs (wear layer, construction, grading), low-emission certification (E0/E1 / CARB2 / no added formaldehyde), proven adhesive quality, and written warranties. Look for consistent manufacturing standards, transparent lead times, and independent reviews or case studies.

- Certified, traceable oak sourcing (FSC/PEFC)

- Engineered construction: 100% birch plywood (for stability)

- Wear layer: 4–6mm (refinishing potential)

- Adhesives: low-VOC / no added formaldehyde

- Suitable for underfloor heating (and installation guidance)

- Clear warranty + documented performance history

Solid Versus Engineered Wood Flooring

Solid wood flooring is now very much in decline. This is due to increased awareness of sustainability and the need to reduce deforestation and changes in the market (such as using underfloor heating, people wanting wider floor boards etc…).

Engineered wood flooring uses about 75% less of the slow growing hardwoods such as Oak. It also utilises the more of the faster growing hardwoods such as birch, eucalyptus and poplar to make the multi-cross-layer plywood backing of an engineered board.

An important factor to consider when comparing engineered wood flooring suppliers is the type of adhesives used. These adhesives not only glue the multi layers of the plywood together but also the top layer of solid oak, maple or walnut or other exotic woods to the plywood base. There are only a few manufacturers of high quality adhesives but hundreds of inferior copies where the longevity of the engineered boards may be in question.

We guarantee all our engineered boards are made using only the best European adhesives that are environmentally friendly with no formaldehyde or other residues that could be harmful especially when underfloor heating is used.

What is Engineered Wood Flooring & Why Use it?

Engineered Wood Flooring comes in a large range of finishes and styles. It also comes in different structures and it is important to understand the implications of how the boards are manufactured to appreciate the effect they can have on the application you want to use the flooring for.

Finishes can range from antique hand distressed to tranquil smooth natural brushed boards all through to rustic and prime finishes and can be used with underfloor heating. You should never confuse Engineered wood flooring with the cheap laminated versions.

There are two basic structures of engineered floors:

1. Cross ply birch plywood back

Sandwich Board where the whole structure is made up of the same species of tree Poplar back where you normally get just two layer of poplar this is the least expensive engineered board. Top quality plywood boards are the foundation for any quality engineered flooring, as good foundations are for a solid house. The plywood is made up of several layers of birch; each layer has the grain running in opposite directions which will ensure that the top layer has a very hard stable surface on which to adhere. You should always look for a 100% birch plywood back to give extra stability. A mixture of woods is not good for the long term stability of any engineered wooden floor.

2. Solid Wood and Engineered boards

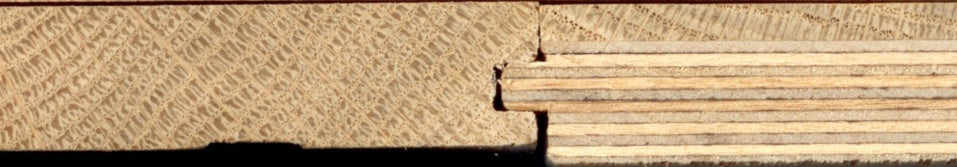

The difference between a solid wood floor board and a good quality engineered floor board that has a minimum top layer thickness of 4mm or 6mm is minimal. Solid boards are normally 18mm thick and good quality engineered wood flooring is 20 to 21mm thick. The picture at the top of this page shows the end section of a solid board next to an engineered board and as can be seen there is no real difference between either within the first 6mm. Therefore engineered boards offer huge advantages over solid wood flooring due to their stability and they will look the same as a solid board.

The picture below shows the end grain of a modern solid oak where the heartwood is near the middle and the board will always “cup” towards the heartwood, this will cannot happen with an engineered board.

Modern Solid Oak Flooring where boards naturally cup to the central heart wood

How are Engineered Floor Boards Made?

Engineered wood floors are made up of a top layer of solid hardwood bonded with modern adhesives to a plywood base. Like any structure, the foundation, which in this case is the plywood, is the part that gives the floor board its stability. Plywood is made from veneers (which are slices of hardwood) about 2mm thick which are bonded together in high pressure presses. The best engineered boards have a 14mm or 15mm thick plywood back. The top of the hardwood flooring is then bonded to the plywood base with a high pressure pressand allowed to cure. Once this is done and the adhesive is cured the boards are then put in a drying chamber (similar to a kiln) to balance the moisture content of each type of wood.

The top veneer or top wood layer of solid hardwood can be anything from 4mm to 6mm. If the top layer is only 2mm then it can get easily damaged and unlike thicker top layers it is harder to repair.

Top quality engineered floors will look no different than solid wood once fitted but are in fact much more stable and do not need to be acclimatised except for the sandwich board and if the installation is over UFH.

Helping the Environment

By choosing an engineered wood flooring board you are helping the Environment. There are many reasons to choose an engineered wooden floor over any other type including solid wood, some are listed below and with issues of global warming and other concerns about our environment we should be looking at buying such a natural flooring solution.

We can manufacture much more flooring from the same tree using engineered wooden flooring. Solid boards are normally 18mm to 20mm thick and with a 6mm top layer we can get three times as much and with a 4mm top layer, four times as much engineered wood flooring!

Engineered floors will not expand and contract like solid wood, you do not need to acclimatise the boards unless fitted over UFH. You can use engineered boards with underfloor heating Engineered flooring can be floated on uneven surfaces or better still glued down Engineered wooden flooring can be used in moisture prone areas of homes and commercial premises, like bathrooms, kitchens, walkways etc. The picture below shows the cross section of an engineered board 20mm thick with a solid 5mm top layer and a multiply birch plywood.

5mm top layer solid oak pressed on to 15mm thick multi layer ply base

Installing Engineered Flooring

There are several methods of fitting engineered floors and the main ones are below:

Floating Floor this is where you glue the tongue and grooves together with a good quality PVA adhesive and just let the boards rest on an underlay or electric heating mat if it is recommended by the manufacturer. Gluing the floor directly to a concrete screed or flat subfloor like plywood or chipboard (Our recommended method using our own SW890 Flooring Adhesive) Secret nailing or screws directly to a plywood subfloor or directly to joists

Poplar Backed Engineered Flooring

This should only be used in certain situations where there is no high traffic and is only really for residential or small office situations. These boards are not structural and are normally laid over 18mm plywood.

Engineered Sandwich Floor Board Construction

These are fairly new to the market and are normally used where boards are wider than 260mm. For example the picture below shows a 340mm wide board that is constructed totally of Oak. This means that the whole board has the same cell structure and is the same species allowing consistent movement which is only restricted by the structure. If you had a solid board like this that is cross cut, as all floor boards are these days, then you would have to drill holes. This means you would screw the boards directly from the top as there would be too much movement which would result in expansion, contraction, warping and cupping which is why you see plug holes in very old boards.

In the sandwich constructed board, picture below, the top layer is 6mm, the middle with the grain going in the opposite direction is 9mm and the bottom layer is 5mm and is also finger jointed:

The first picture above shows a slice of a 20mm thick sandwich board. This shows how the grain runs in the opposite direction. The lower picture shows the strips of the middle layer, 6mm top layer and 5mm bottom layer. This means that the expansion and contraction are controlled by the middles layer’s grain running in the opposite direction to the top and bottom layer.

Speak to our experts

We are always here to help and give unbiased advice as the products we make. For more information on the multitude of benefits of choosing us as your wood flooring suplier please see our “Why Choose Us” guide, or give a call on 01666 504 015.

Frequently Asked Questions About Choosing a Reliable Oak Flooring Supplier

Choosing the right oak flooring supplier can feel complex, especially with so many variations in construction, sustainability claims, and performance standards across Europe. The FAQs below answer the most common questions we’re asked by homeowners, designers, and contractors, helping you understand what really matters when assessing product quality, reliability, and long-term suitability for your project.

- What certifications should an oak flooring supplier provide in Europe?

Look for clear, verifiable sourcing and compliance documentation. Common indicators include FSC or PEFC certification (or equivalent chain-of-custody evidence), plus technical datasheets that confirm performance and indoor air quality standards. A reliable supplier should be able to provide paperwork on request rather than vague claims. - Is engineered oak more sustainable than solid oak?

Often, yes. Engineered oak uses a thinner oak wear layer on top of a multi-layer core, which can significantly reduce the amount of slow-growing hardwood required per square metre compared to solid oak. Sustainability still depends on responsible sourcing and manufacturing, so ask about timber origin and material composition. - What wear layer thickness is best for engineered oak flooring?

A 4–6mm oak wear layer is a strong benchmark for durability and future refinishing potential, helping engineered boards perform more like solid oak in day-to-day life. Thinner wear layers (e.g., around 2–3mm) can be more vulnerable to damage and may limit sanding/refinishing options. - What is the best backing for engineered oak flooring?

A multi-layer birch plywood core is widely regarded as the most stable option because each layer’s grain runs in alternating directions, reducing movement. Mixed-species cores and lower-grade plywood can be less consistent and may increase the risk of warping or long-term instability. - Are engineered oak floors safe with underfloor heating?

Quality engineered oak is generally well-suited to underfloor heating because it is more dimensionally stable than solid wood. Safety and performance depend on following the supplier’s UFH guidance (subfloor moisture limits, temperature ramp-up, maximum surface temperature, and the recommended installation method). - What should I ask about adhesives and formaldehyde emissions?

Ask what adhesive system is used, whether it is low-VOC, and what formaldehyde/emissions standard the product meets. This matters even more with underfloor heating, where heat can increase off-gassing from inferior adhesives. A reliable supplier should be able to share emissions documentation and explain their adhesive choices clearly. - How can I tell if engineered flooring is high quality?

Check for transparent specs: a stable core (ideally birch plywood), a meaningful wear layer (typically 4–6mm), consistent board thickness, and clear grading information. High-quality suppliers also provide proper installation guidance, realistic maintenance advice, and a written warranty backed by evidence (reviews, case studies, track record), not just marketing claims. - What’s the difference between engineered oak and laminate?

Engineered oak has a real oak top layer bonded to a structural core, so it looks and behaves like wood and can often be refurbished depending on wear layer thickness. Laminate is a synthetic photographic layer on a fibreboard core, designed to mimic wood but it is not real timber and typically cannot be sanded or refinished.

Join our mailing list

Receive the latest news, offers and inspiration straight to your inbox.